Best Air Brush Compressor for Tools and Painting

A t SGS, there is a huge range of direct drive and belt drive air compressors. We understand that it can seem daunting to try and pair your air tools with a specific air compressor. Especially as the range of choices available is so broad. Air compressors can be used for all manner of work on vehicles and home. For example, touching up the paint work, wrenching off wheel nuts, cutting metalwork etc. How do you know which one you should use? The best air compressor isn't always the right air compressor for the job. We've put together a simple user guide and check list to help you narrow the field and decide which compressor is worth your investment.

Quick Start Guide

1. What will you be using the compressor for?

Having an understanding what you will be using your air compressor for is the most important factor when looking to buy a compressor. All compressors come with specific warranties to cover infrequent use for DIY jobs or frequent . Make sure you choose the right compressor for your application. If you have a specific job in mind then check out our compressor kits with everything you need to get started.

2. CFM requirement

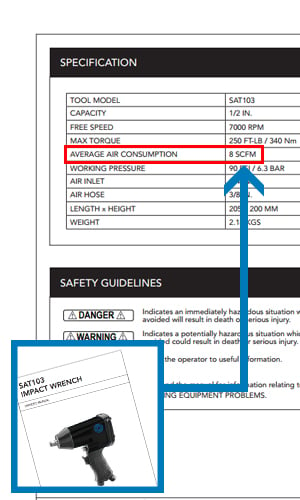

CFM requirement - the single biggest consideration when buying a compressor. Knowing what CFM your air compressor needs to produce in order to power all of your air tools. Find the SCFM requirement of your tool from it's manual or technical specification.

Example: if you want to run a spray gun (6 SCFM):

6 SCFM x 1.2 = at least a 7.2 CFM compressor

3. Choosing a tank size

With tank sizes ranging from 6 litres to 500 litres+, choosing the perfect capacity air tank / receiver will seriously affect the performance of your compressor. To find the minimum tank size of the compressor you need multiple your tool's required SCFM by 6.

For example, if you run an impact wrench (8 SCFM):

8 SCFM x 6 = at least a 48 litre compressor tank

4. Oil-less or oil compressor

Oil-less compressors are low maintenance and free from contaminants. A standard oiled generally compressor will produce a larger output and run quieter

1. Direct Drive or Belt Drive?

We split our range of compressors into two specific ranges - direct drive and belt drive - each with it's own specific warranty tailored for its intended use. If you're a DIY user, hobbyist or occasional user of an air compressor, we'd suggest one of these SGS compressors. Competitively priced and complete with a 2 year domestic warranty – SGS compressors are very portable and perfect for occasional nailing, stapling, drilling, tyre inflation, air brush painting or blow cleaning. Designed with the DIY user in mind, they're ideal for working in the garage at the week end or a track day.

If you're going to be using a compressor more consistently or even every day, we stock a wide range of commercial and workshop compressors. SGS and ABAC belt drive compressors are designed for a variety of applications. Our professional portable compressors are perfect for service engineers, upholsterers and many other mobile users, while our stationary compressors are ideal for workshops and industrial settings.

Direct Drive Compressors

This range of direct drive compressors is designed for home use, hobbyists, and semi-professional applications. Fantastic value for money and perfect for anyone wanting to occasionally use a compressor. With two years domestic warranty and free delivery on orders over £100 – these compressors are among the best in the consumer market.

Belt Drive Compressors

Perfect for workshop and industrial set ups, these compressors come with anti vibration feet for minimal noise pollution, and large receiver (air tank) for heavy duty usage. Whether portable or stationary - electric, petrol or diesel powered, our industrial air compressors allow you to have the choice and control in deciding exactly what your business needs are.

2. Understanding Required CFM

One of the most important consideration when purchasing a new air compressor is the air flow the compressor can deliver. Air tools have certain requirements to run at optimum capacity. More important is the Required SCFM or Standard Cubic Feet per Minute.

All air tools will have a required SCFM, but in general smaller air tools require between 0-5 SCFM. While larger tools can need 10 or more SCFM.

CFM stands for Cubic Feet per Minute and is the volume of air the compressor can pump out per minute.

The first thing you need to work out is how much air will you need to power your tool. To work this out we need to know how much air flow the compressor produces and how much your tool requires to run. Most air tools will have specific requirements for air volume and pressure. Your compressor must meet these requirements for the tool to function the best they can.

Working out your CFM requirement

- Find the required air flow (SCFM)

of your air tools. This information will be in your tools user guide or manufacturers website. - If you're going to be running multiple tools you'll need to add together the individualSCFM of each tool. Most DIY compressors are designed to run only one tool at a time. You can successfully run several tools simultaneously on larger more commercial compressors.

- To find the minimum required CFM of the compressor you need multiply your tool's required SCFM by 1.2

Example: if you want to run a spray gun (6 SCFM):

6 SCFM x 1.2 = at least a 7.2 CFM compressor

This is a rough guide only. Larger compressors with higher CFM and bigger tanks will always give you better performing tools. You may prefer buying the largest compressor within your budget.

Typical SCFM Requirements

These are some typical values for various air tools. You should always check the exact requirement of your tool by consulting its user guide.

| Tool Type | Req SCFM's | Tool Type | Req. SCFM's | Tool Type | Req. SCFM's |

|---|---|---|---|---|---|

| Angle Disc Grinder | 6 SCFM | Dual Action Sander | 6 SCFM | Ratchet 1/4" | 3 SCFM |

| Air Drill 1/2 | 4 SCFM | Grease/caulking gun | 4 SCFM | Ratchet 3/8" | 4 SCFM |

| Air Drill 3/8 | 4 SCFM | High Speed Grinder 5" | 4 SCFM | Sand Blaster | 4 SCFM |

| Butterfly Impact | 3 SCFM | Imapct Wrench 1/2" | 5 SCFM | Spray Gun | 6-18 SCFM |

| Air Hammer | 4 SCFM | Impact Wrench 3/4" | 7 SCFM | Straight Line Sander | 7 SCFM |

| Cut Off Tool | 4 SCFM | Nailer | 1 SCFM | ||

| Die Grinder | 8 SCFM | Orbital Jitterbug Sander | 6 SCFM |

CFM vs FAD

CFM (FAD) is generally third less than CFM (Displacement), if your air compressor is advertised as 10 CFM (displacement), the Free Air Delivery (FAD) is probably around 6.6 CFM.

FAD is "free air delivery" and is the volume of air actually discharged. Compressors are always listed with the theoretical displacement, not the actual amount of air delivered. FAD is far more useful the CFM as you can see the actual "power" a compressor has available for tools etc.

TOP TIP: Air flow is lost through air hoses, hose fittings, filters, lubricators, and especially through quick-connect couplings. If you do plan to run your air tool some distance away from the actual compressor or with any of these peripherals, you will need to consider this pressure drop when choosing your compressor. The more CFM your compressor produces, the better your tool will run, even with longer hoses and more fittings.

TOP TIP: Never use extension leads with an air compressors! The voltage drop from an extension cable can damage the air compressor motor. Instead use a longer air hose.

Working Pressure

The pressure generated inside the tank of an air compressor is measured in Bar and Pounds Per Square Inch – or PSI. Most compressors have a working pressure of 8 bar / 115 PSI which is more than sufficient for DIY and hobby air tools (normally around 90 PSI)

Some of the more powerful air compressors we sell in our commercial range have higher working pressures (145 PSI+). Again, you can always check to see what working pressure is required for your air tool by looking at the user manual or contacting the manufacturer.

Working out your required tank size

To find the minimum tank size of the compressor you need to multiply your tool's required SCFM by 6.

For example, if you run an impact wrench (8 SCFM):

8 SCFM x 6 = at least a 48 litre compressor tank

Again, this is a rough guide and the larger tank your compressor has, the better the performance of your tool. Below is a table of our range of compressors to help you choose the right one for your applications.

| Model | CFM | Discharge pressure (psi) | Tank Size (L) | Direct Drive | Belt Drive |

|---|---|---|---|---|---|

| SC6C | 6.3 | 115 | 6 | ✔ | |

| SC6H | 5.7 | 115 | 6 | ✔ | |

| STARTO15 | 6.4 | 115 | 6 | ✔ | |

| STARTO20P | 8.1 | 115 | 6 | ✔ | |

| SC8H | 5.5 | 115 | 8 | ✔ | |

| SC24L | 5.5 | 115 | 24 | ✔ | |

| POLEPOSITIONO15 | 6.4 | 115 | 24 | ✔ | |

| POLEPOSITIONO20P | 8.1 | 115 | 24 | ✔ | |

| POLEPOSITIONL30P | 11 | 145 | 24 | ✔ | |

| SC24H | 9.6 | 115 | 24 | ✔ | |

| SC24S | 9.5 | 115 | 24 | ✔ | |

| MONTECARLOO20P | 8.1 | 115 | 50 | ✔ | |

| MONTECARLOL30P | 11 | 145 | 50 | ✔ | |

| SC50V | 14.6 | 115 | 50 | ✔ | |

| SC50H | 9.6 | 115 | 50 | ✔ | |

| SC50S | 9.5 | 115 | 50 | ✔ | |

| PROA29B50CM2 | 8.9 | 145 | 50 | ✔ | |

| PROA29B50CM3 | 11.2 | 145 | 50 | ✔ | |

| SC90B | 14.6 | 145 | 90 | ✔ | |

| PROA29B90CM3 | 11 | 145 | 90 | ✔ | |

| PROA39B90CM3 | 14 | 145 | 90 | ✔ | |

| PROA39B150FM3 | 13.8 | 145 | 150 | ✔ | |

| PROA39B150FT3 | 13.8 | 145 | 150 | ✔ | |

| SC150B | 14 | 145 | 150 | ✔ | |

| PROA39B200CM3 | 13.8 | 145 | 200 | ✔ | |

| PROB4900200FT4 | 18 | 160 | 200 | ✔ | |

| PROB5900B200FT5.5 | 22.9 | 160 | 200 | ✔ | |

| PROA39B200FM3 | 13.8 | 145 | 200 | ✔ | |

| PROA39270FM3 | 27.6 | 145 | 270 | ✔ | |

| PROB6000270FT7.5 | 28.9 | 145 | 270 | ✔ | |

| PROB7000270FT10YD | 42.4 | 145 | 270 | ✔ |

Electric, Petrol or Diesel

With a conventional electrical air compressor you'll always be limited with where you can set up and get on with your project as you need to be near a mains power outlet. However with a petrol or diesel driven compressor you have total flexibility to set up wherever you need to be without hindrance. Perfect for those semi-professional and professional users.

Standard vs. Oil-less Air Compressors

Oil-less compressors have become increasingly more popular for at home and light DIY use. This table should help to understand the pros and cons of an oil-free compressor vs a standard oiled compressor so you can make an informed buying decision.

| Oiled Air Compressors | Oil-less Air Compressors | |

| Lubrication | Standard air compressors use a lubricating oil to effectively and reliably to keep the pistons moving in a good working order. | In oil-less compressors the pistons are permanently pre-lubricated in a material such as Teflon. |

| Maintenance | The oil will need changing periodically. Neglecting maintenance will cause irreversible damage and invalidate your warranty. | No oil means no oil changes, meaning minimal maintenance requirements. |

| Weight | Standard compressors weigh considerably more than oil-free compressors as a rule. | Oil-less compressors require less parts, therefore they tend to be lighter the alternatives. |

| Usage | Standard compressors are durable and hard-wearing. Most industrial and commercial air compressors will utilize oil. | Teflon coated cylinders will get worn down over time, meaning your piston will start to get dry and performance will suffer. . |

| Noise | Standard compressors tend to be a lot quieter than oil-less alternatives, purely because they're liquid lubricated. | |

| Contaminates | Having an oiled compressor means a chance of getting contaminates in your air line. If you're using a spray gun, it may ruin your work. | No oil means no contaminates, making these compressors popular with spray painters and clinical settings. |

When you start looking at the more professional air compressors you'll start seeing a larger variety of power options. You might want a 400V, three-phase power supply for a commercial setting, or a petrol/diesel compressor for more flexibility.

Compressor Kits

If you're just starting out on a new hobby, or you want to take the hassle out of the buying process, take a look at our fantastic value bundle offers to get the process started. Whether you're interested in drilling, ratcheting, wrenching, grinding, stapling, nailing or painting, we'll have the right bundle to kick start even the most ambitious DIY project. Our premium start up kits, ensure you get everything you need at an unbeatable price. Our bespoke bundles are made up of high quality tools and SGS compressors. All delivered free to the UK mainland, our special offers page is the best way to begin the buying process.

Stapling & Nailing

Our 6 litre, 5.7 CFM oil-less compressor is a fantastic low maintenance compressor anyway, but when you pair it with the SAT403 air nail and staple gun you get a really special, powerful tool combination. This kit is brilliant for upholstery, and home maintenance tasks, an ideal starter pack. This versatile air gun is easy to switch between nailing and stapling. Making it the perfect tool for all kinds of jobs. Holding 100 brad nails or 80 staples, you don't have to reload often during a job. Air hose, couplers and gauge included. We have so much faith in our products that all SGS start up kits come with a 2 year warranty.

5 Piece Starter Kit

Our 24 litre air compressor and tool kit provides you everything needed to begin working. The 5 metre spiral air hose is fitted with 2 quick release couplings, meaning it's compatible with all the tools provided in the kit. The professional style paint spraying gun boasts a 0.6 litre gravity-fed cup, a 1.5mm nozzle and is suitable for most conventional painting jobs. The oil spray gun has a 0.9 litre capacity, perfect for spraying things such as engine de-greaser, and insecticide. With the tyre inflator and pressure gauge, you can easily check the pressure of almost any automotive, bicycle, etc, tyres

Spraying Kit

Our 50 litre high flow reciprocating air compressor has the capacity and delivery to ensure you always get superb results. The large 50L tank makes this kit suitable for serious enthusiasts and semi-professional use. This kit is fully equipped with a HVLP gravity fed professional spray gun, 10m 6mm rubber hose with quick couplers, mini air filter and 1 litre of compressor oil. Our compressor spray gun guide has all the info you need to get up and running.

71 piece Tool Kit

As well as a high capacity 14.6 CFM air compressor with 3.0HP motor. With this kit you receive a huge array of tools and accessories including; Impact Wrench, Die Hammer, Ratchet & Grinder, two rubber hoses with quick release couplers, air filter, water trap, regulator and lubricator, compressor oil, air line oil and all the couplers you need to get started. The kit is designed to make air compression tools simple to use, efficient, and cost effective.

Still need help?

Best Air Brush Compressor for Tools and Painting

Source: https://www.sgs-engineering.com/help-advice/air-compressor-buying-guide-which-compressor-should-i-order/

0 Response to "Best Air Brush Compressor for Tools and Painting"

Post a Comment